Flood Barrier Australia – Operation and Maintenance

Flood Barrier Australia – the passive, hidden Flow Defence (FD) flood barriers activate without human intervention, designed and manufactured in Australia.

Installation Location

FD Flood Barrier Australia intercept flood water in an underground chamber. In minor storm events the buoyant barrier will not activate. A submersible pump keeps the chamber drained to ensure that the barrier will only activate when necessary.

If more water enters the chamber than the pump can displace, the chamber will fill with water. While the chamber fills with water a foam filled buoyant barrier will float to the surface.

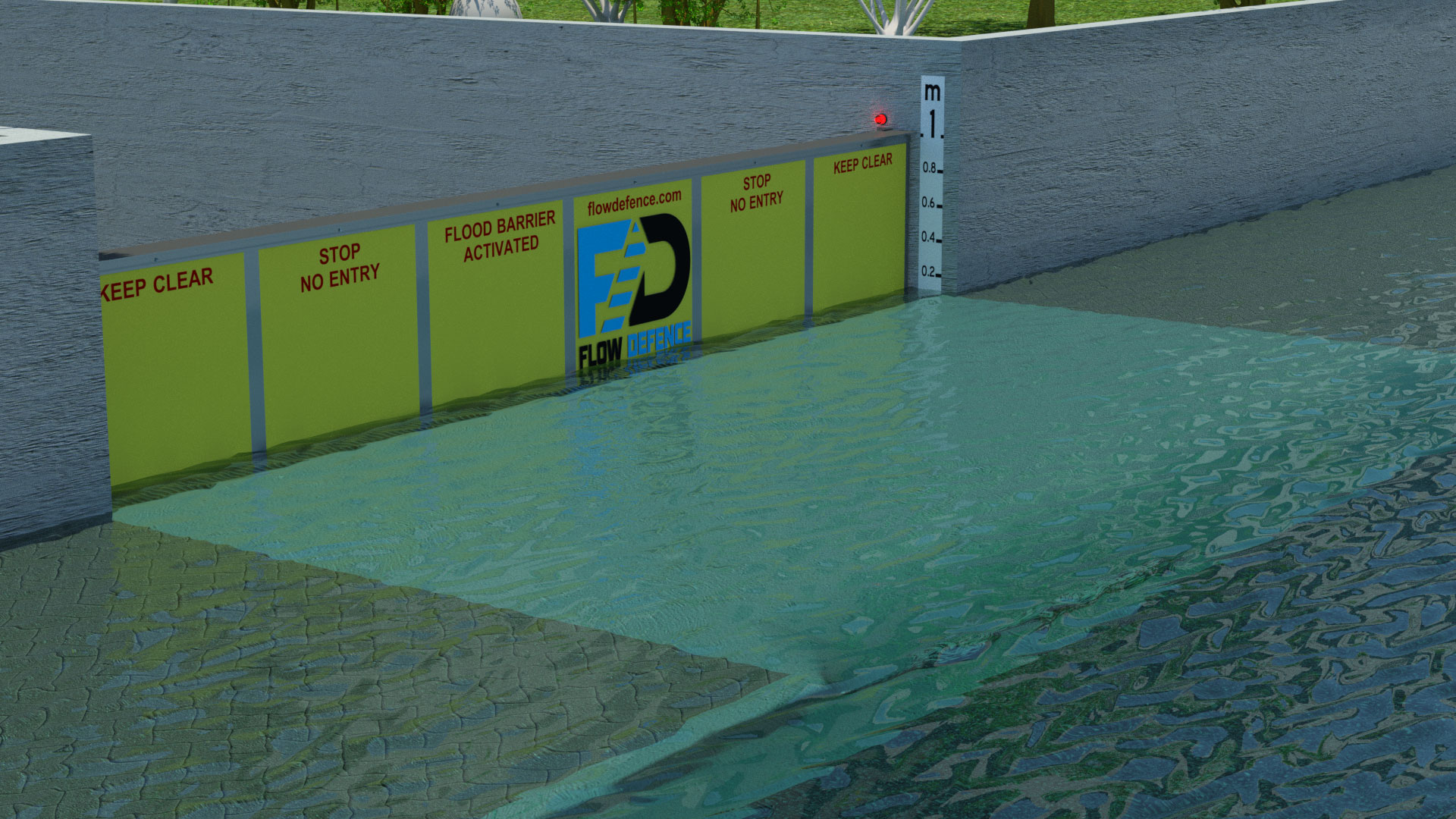

For public safety. warning signs, lights and an audio alarm alert vehicles and pedestrians that the barrier has been activated. The barrier will raise in just over one minute and is fixed in place before water levels on the road increase.

Sealing Mechanism

The FD Flood Barrier Australia system is a self-contained unit since the collection chamber houses the inlet grate and the buoyant barrier.

The Flood Barriers sealing operation is all done from the downstream side of the chamber. This allows full unrestricted access to the upstream side of the barrier for maintenance. Optional pre-screening baskets can be installed.

Floatation applies vertical hydrostatic forces, retained flood water on the upstream side applies horizontal hydrostatic forces. Both of these forces act on the barrier and compress a seal to prevent leaks.

Seals remain above water level as the barrier floats. Sealing mechanisms become watertight before floating debris can be caught between barrier and sealing frame.

Angled lugs guide seals during compression and act as a canter lever point by providing a fixed connection between vertical barrier supports and the concrete chamber. This configuration reduces barrier deflection from hydrostatic forces.

Detained Flood Water

FD Flood Barriers remain in the upright position until flood waters recede and the collection chamber is drained.

The Flood Barrier can be lowered using one of three methods:

- Submersible pump installed within the FD chamber collection sump. This is activated by a float switch, draining the pit automatically and lowering the barrier provided power is still available to the site during a flood event.

- The self-siphon system will prime when flood water fills the collection chamber. A tamper proof valve (valve with no handle) can be opened after flood water recedes. The retained water captured by the FD interception chamber will then be drained into the underground carpark (~3,000L) lowering the barrier at the same time.

- Any pump on a maintenance vehicle with a suction hose can access the FD interception chamber by removing access grates from the property boundary at ground level. Water in the collection chamber can then be discharged to the street kerb or landscaped area while lowering the barrier.

Flood Barrier Australia – Maintenance Procedures

Flood Barriers should be de-sludged using an educator truck after every flood event in which the barrier activates. The FD Flood Barrier is not required to be moved during maintenance. The sealing mechanisms are located below ground level and are out of direct sunlight minimising any environmental or impact hazards.

- Advise all concerned parties of the proposed date and time of cleaning.

- Obtain approvals from the appropriate authorities.

- Prepare necessary Safe Work Method Statements.

- Provide barricades in working areas and signs to prevent injuries to public or staff.

- Remove inlet grates.

- Lower vacuum hose, remove debris and sediment while cleaning all components with a high pressure hose (most Wet Vac combination trucks have this facility).

- Remove vacuum hose and replace inlet grates.

- Record site location, date and time of clean and duration of clean.

Flood Barrier Australia – Inspections

We believe that the unit life will be enhanced while using Flow Defence staff to monitor and maintain the Flood Barrier.

Flow Defence Flood Barriers should be inspected (half yearly) and serviced (annually) to ensure they are clean and free from material buildup.

6 Month Inspection:

- Interception chamber sump inspected for material build up (water, sediment or debris).

- Flexible seal and guide frame inspection.

- Full maintenance report.

- Determine if service is required.

Cleaning After Unit Operation:

- Remove sludge and sediment using Vac Truck.

- Clean components with high pressure spray.

- Flexible seal and guide frame inspection.

- Full cleaning report.

Flood Barrier Australia – Service and Repairs

Should repairs be required the barrier can be removed if necessary since the flexible sealing mechanism is mounted to the FD Flood Barrier.

Order of Removal:

- Inlet grates and frame.

- Submersible pump.

- Barrier using hiab lift.

Alternatively for minor repairs and detailed inspection, the collection chamber can be filled with water while raising the barrier above ground level for access.

FD Flood Barriers have a 10 year warranty, in addition all internal components and workmanship and will rectify any problems at no charge. Damage caused due to vandalism and outside parties is not covered by the FD warranty.

Flow Defence™ is protected by Trade Mark Number 1880447

Flow Defence™ Self- Activating Flood Barrier is Protected by International Granted Patents WO/2015/120516

© 2026 Flow Defence™ Pty Ltd