Flood Water Barrier – Concealed and Self Closing

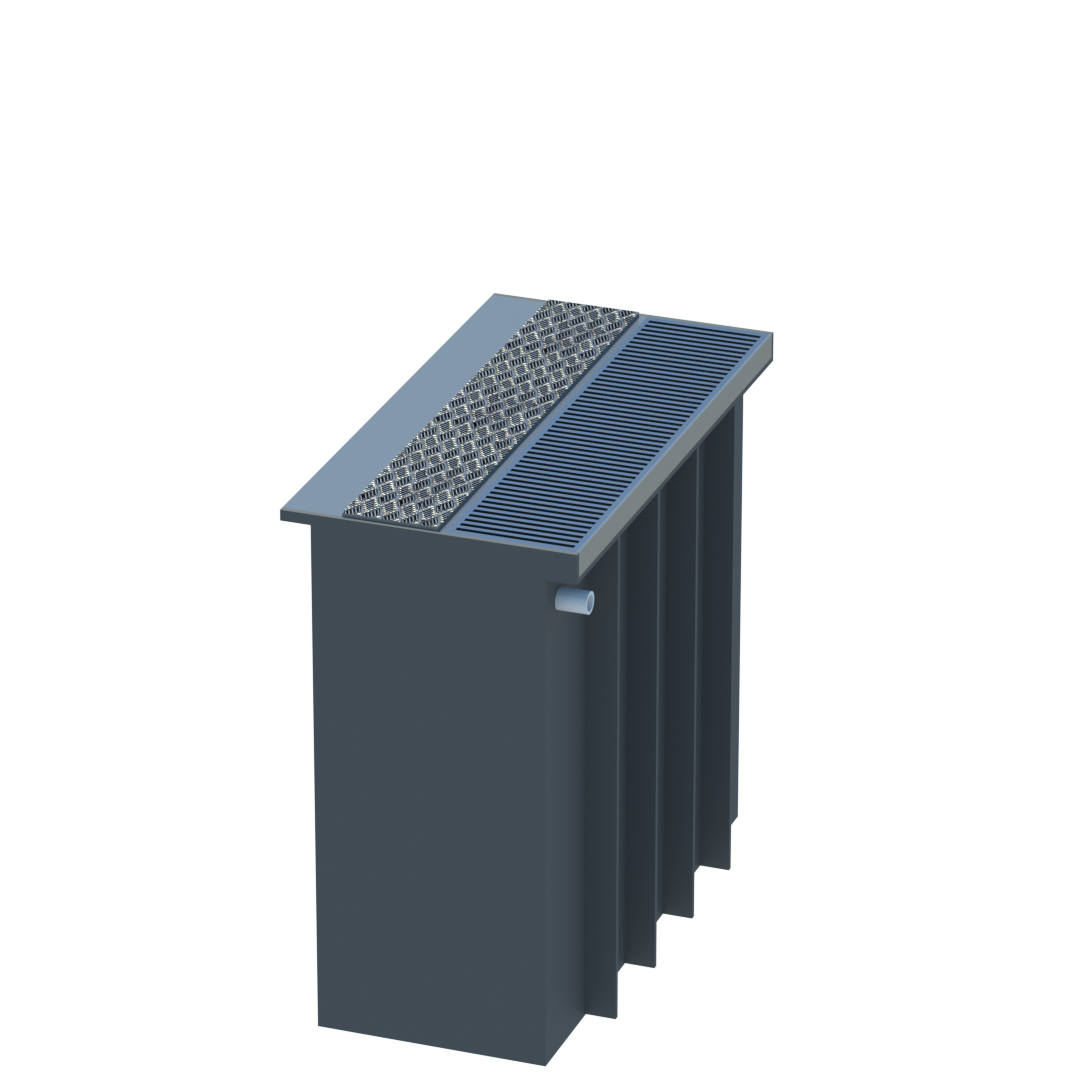

Flow Defence concealed and self closing Flood Water Barrier systems avoid conflicts with existing underground services. The system is a completely self contained unit. The entire flood water barrier can be installed within the property boundary and does not require additional service pits to operate.

Unlike other systems on the market, debris does not need to be removed after activation in order to lower the barrier. A unique patented design ensures the barrier does not need to be removed in order to access the underground chamber.

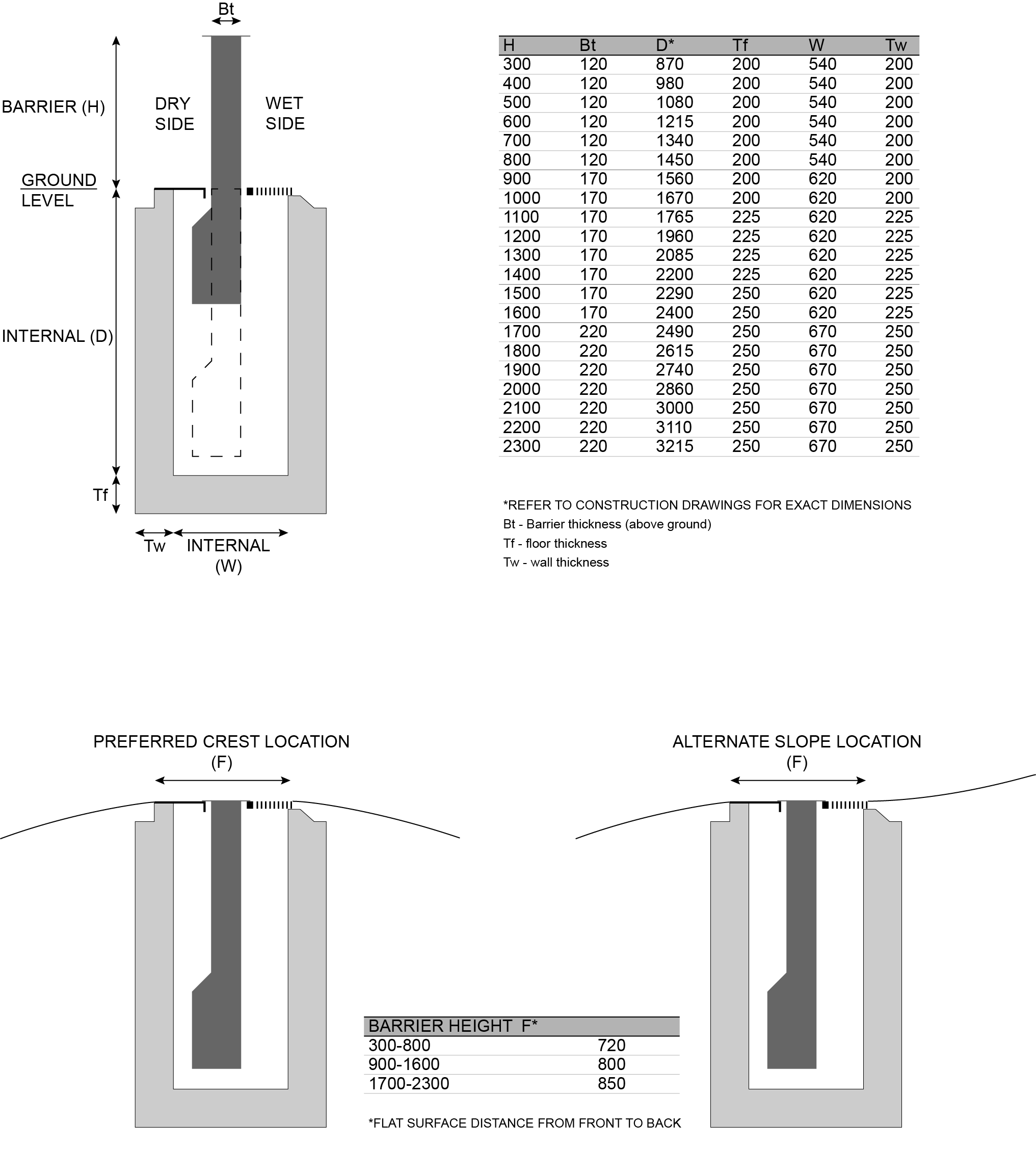

Flood Water Barrier Dimensions and Location

Flood Water Barrier Features

Applications: Domestic, commercial and industrial access points including but not limited to driveways, basement carpark ramps, doorways, walkways, stairwells, lift shafts and gateway openings.

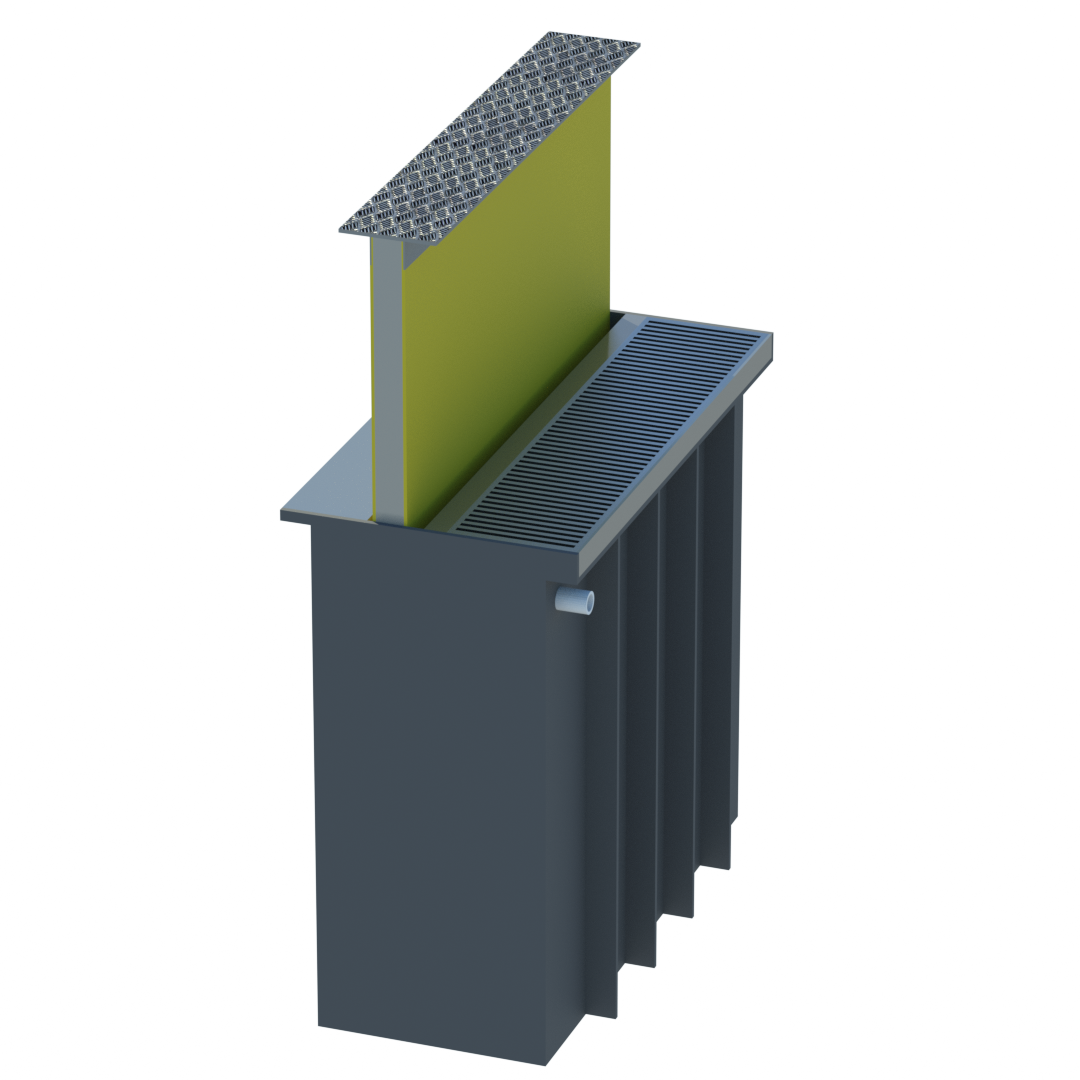

Installation: Hidden below ground level, the small surface area is independent of the flood water barrier height. The design is a self contained unit eliminating the need for deep trenching and remote service pits.

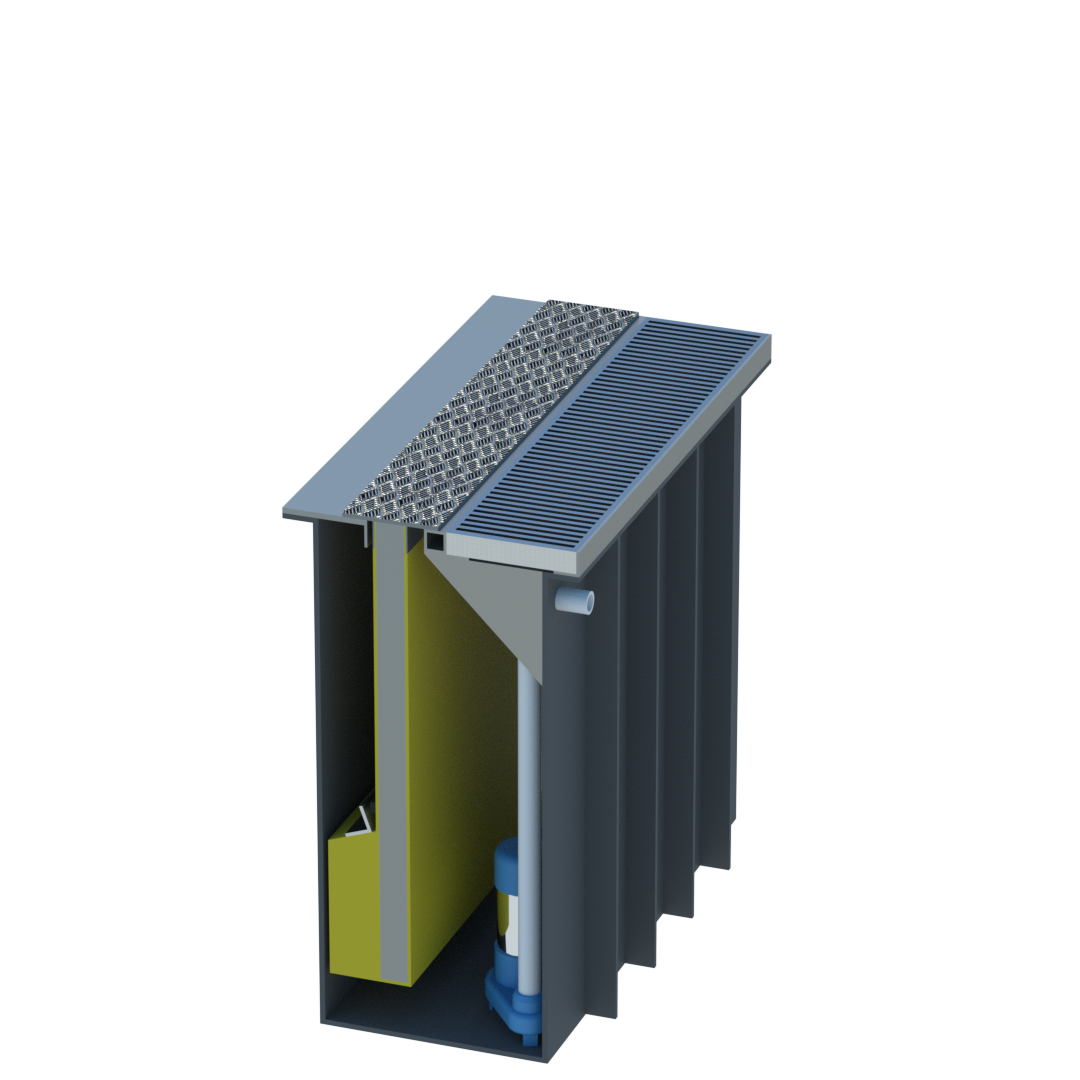

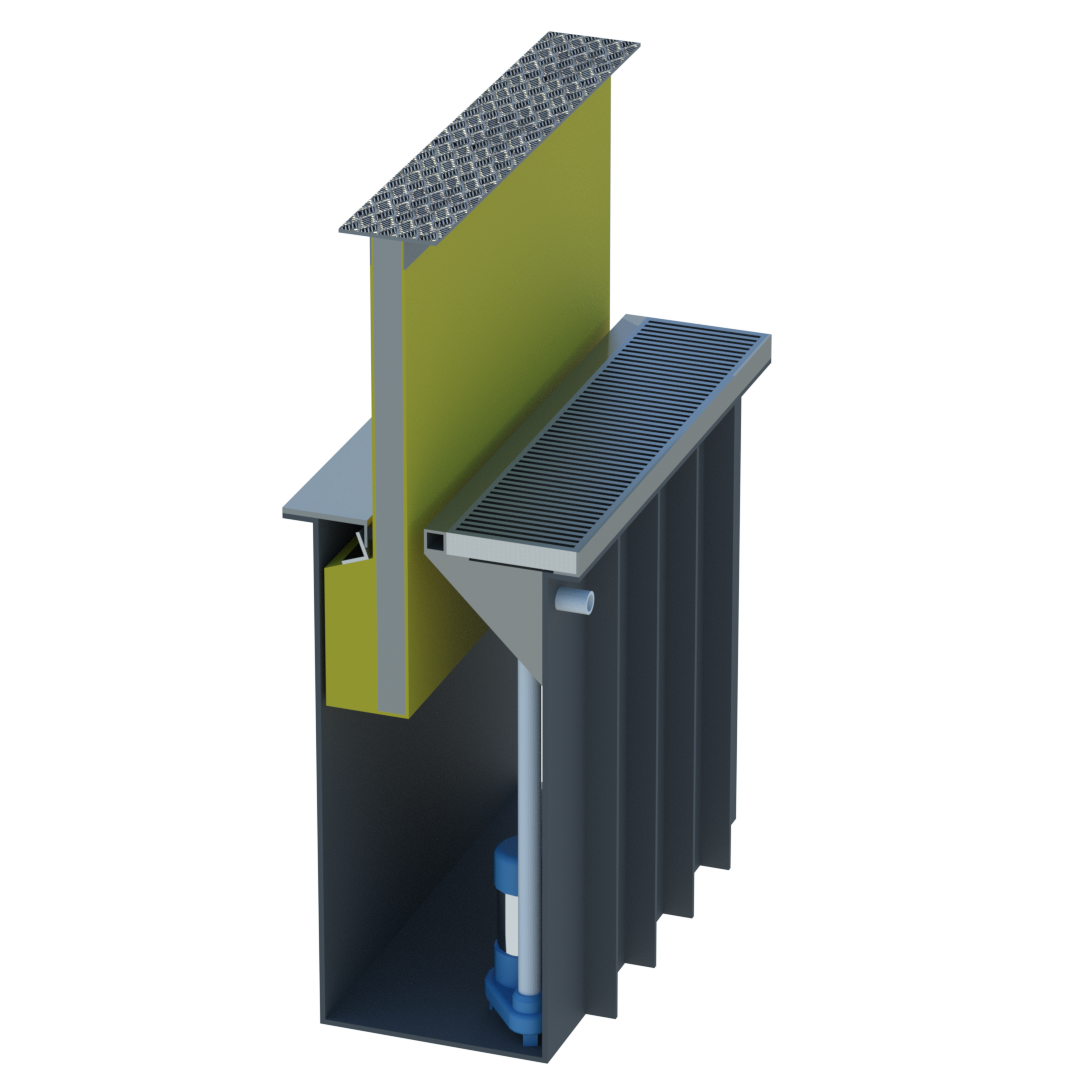

Operation (activate): Concealed and self closing, flood water is intercepted by surface grates and collected in an underground chamber, as the chamber fills with water a buoyant barrier raises to the surface.

Operation (deactivate): The chamber does not free drain to the stormwater network, this is to prevent surcharging which could raise the flood door earlier than necessary.

Maintenance: A submersible pump is used to drain water out of the chamber and can be accessed from ground level without removing the flood water barrier.

Flood Water Barrier Principles of Operation

- The concealed and self closing flood water barrier system does not require electricity to operate. It is fully activated by rising flood water being captured within the interception chamber

- The chamber has removable grates with 25mm spacing’s. This prevents any large debris from entering the chamber and also allows access into the chamber for routine maintenance

- A submersible pump is located inside the chamber to lower the barrier after a flood event. The barrier will only raise when more water enters the chamber than can be pumped out

- A sump below the barrier can store any particles that sink to the bottom of the chamber. These particles can be removed with a vacuum truck during standard maintenance or after the barrier has been activated if necessary

- The sealing mechanism is mounted to the barrier and cannot be tampered with while the barrier is retracted below ground level

- The seal on the barrier is mounted in such a way that it is always above the water level within the chamber. This way when it raises into position the seal will not be prevented from compressing by floating debris

- The barrier has been designed to have additional buoyancy in case a tree branch or other such object falls over the top of the barrier during a storm before it activates. This additional buoyancy is dependent on the barrier size but it equates to about 200kg of lifting force

Flood Water Barrier Component Materials

| Material | Description | Components |

|---|---|---|

| Aluminium | 6082 Aluminium is light weight, has excellent corrosion resistance and is the highest strength of the 6000 series structural alloys used in highly stressed applications such as bridges, cranes and marine environments. | Buoyant barrier internal frame |

| Concrete | C1 Concrete exposure class for brackish, saltwater, marine applications and potential acid sulphate soil (PASS) and acid sulphate soil (ASS) environments in permanently submerged or zones subject to repeated wetting or drying. | Interception chamber body |

| HDPE | High Density Polyethylene (HDPE) plastic is a ridged high tensile strength sheet. The material is sturdy and resists vigorous handling, stabilised against ultraviolet light, is resistant to both hot and cold extremes and is used in the mining, oil/gas, agriculture, marine and chemical storage industries. | Buoyant barrier surfaces |

| Hot-Dip Galvanising | Galvanising provides outstanding corrosion performance in a wide variety of environments. The galvanising process creates a durable, abrasion-resistant coating of metallic zinc and zinc-iron alloy layers which are bonded metallurgically to the steel and completely covers the item providing a number of significant advantages. It provides outstanding toughness, resistance to mechanical damage and slows corrosion to about one sixteenth that of steel. | Interception chamber grates, frames and fasteners |

| Polyurethane Foam | Polyurethane Foam has a closed cell structure and has better insulation properties then many other insulation materials. Polyurethane foam is widely used for marine buoyancy. One cubic metre of 35kg/M³ polyurethane foam would have a positive buoyancy of 965kg. | Buoyant barrier core |

| Stainless Steel | 316 Stainless Steel is a chromium-nickel-molybdenum austenitic stainless steel with good strength and excellent corrosion resistance, as supplied in the annealed condition with a typical brinell hardness of 175.Characterised by high corrosion resistance in marine and industrial atmospheres. The addition of 2% to 3% of molybdenum increases its resistance to pitting corrosion and improves its creep resistance at elevated temperatures. | Buoyant barrier internal frame fasteners |

Flow Defence™ is protected by Trade Mark Number 1880447

Flow Defence™ Self- Activating Flood Barrier is Protected by International Granted Patents WO/2015/120516

© 2026 Flow Defence™ Pty Ltd